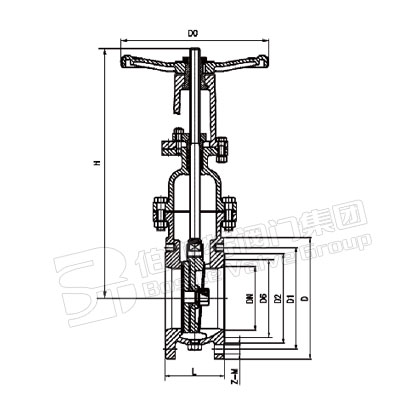

High abrasion discharge valve

Nominal diameter: DN50~1000 (mm)

Nominal pressure: 1.0-10.0MPa

[Essential information]

Specification for design of high antiwear slag discharging valve with

reference to the implementation of GBT12234, is the study of common I

company and the United States and the majority of users Webster company,

according to the problems in use, has experienced four generations of

product optimization and improvement of the domestic and foreign

advanced wear-resistant slag valve products, has won the national

patent. The patent No. 201220482529.8. The product uses straight flow

design, short length of the structure, compressive ability, suitable for

nominal pressure 1.0-10.0MPa, nominal diameter DN50-DN1000, which

solves the conventional flat knife gate valve often used in similar

conditions of leakage, gate thin anti pressure deformation in serious

leakage, suitable working conditions of small pressure range etc..

[Valve structure drawing]

[Standard parameter]

| Design standard | GB/T12234、ASME B16.34、API600 |

| Connection standard | GB/T9112-9124、HG20592-20605、JB/T74-90、ASME B16.5、ASME B16.47 |

| Structural length | GB/T12221 |

| Test and test | GB/T13927、JB/T9092、API598 |

[Valve features]

1,

high carbon steel, slag anti-wear valve castings of stainless steel or

dual phase steel material, Silica Sol precision casting process, casting

dimension precision, surface roughness can reach CT4-6, Ra6.3-12.5

valve, clean and beautiful appearance, no casting defects.

2, the

product is in the structure of the valve cover will be increased, the

conventional flat gate knife gate valve seal into the stem seal, the

seal forms a simpler and more effective, prevent the occurrence of

leakage, the valve protection work in the field and operating

environment.

3, the valve adopts parallel gate and inclined angle of 5

degrees wedge combination structure, compared with the conventional

plate knife gate valve, strength and pressure resistance ability, no

deformation, sealing performance better. When the valve is closed, the

extrusion pressure provided by the 5O wedge enables the sealing surface

of the parallel gate to form sufficient sealing on the sealing surface

of the valve body to prevent the leakage of the valve.

4, before the

parallel gate valve and 5 degree wedge design with spherical washer, the

spherical washer can be in in the process of closing the valve, the

wedge inclined 5 degrees according to the outlet of the valve body

inclined angle, automatically adjusted to a certain angle in the circle,

the inclined wedge to 5 degrees in the body posted on the outlet slope

better, can produce thrust extrusion inclined outlet of the valve body

evenly delivered to parallel gate, can effectively eliminate the error

trace two produced in the processing time, simplify the product

processing and assembly process.

5, the gate off effect, can effectively solve the leakage phenomenon of slag and fiber media gateway rear.

6,

the stem is made of stainless steel, after heat treatment, the overall

processing, and 5 degrees wedge through the "T" groove connection, to

ensure the strength of the stem.

7, the valve body and gate sealing

surface can be welded hard alloy or spray WC treatment, the flow channel

can be painted in accordance with customer needs WC, ceramic powder, in

order to improve the wear resistance of products.

8, the valve

outlet flow channel structure is reasonable, the design has automatic

slag mouth, no residue, open and close flexible, non blocking.

9,

optional drive mechanism, the commonly used driving types are manual,

bevel gear drive, electric, pneumatic, hydraulic, etc., which can meet

the needs of simple drive, but also to meet the needs of remote

automatic control.

[Adaptive condition]

Widely

used in the iron and steel industry blast furnace water slag and slag

discharge system, phosphate rock, phosphorus chemical, iron ore, copper

ore, aluminum ore pulp, as well as coal, chemical, sulfuric acid and

other liquid pipe network, power plant slag system and so on.